Materials &

Processes

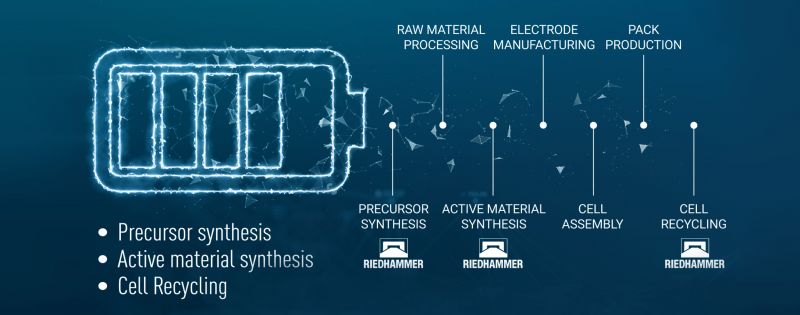

Industrial facilities in the battery sector perform thermochemical processes such as calcination of precursor cathode active material (pCAM) to cathode active material (CAM) or purification and heat treatment of carbon-based anode active materials (AAM).

Processes

- Calcination is particularly important for the overall process, producing the final chemical composition of the NCM.

- The accuracy of the thermal treatment is directly reflected in the quality of the final product.

- Thermal treatment control is one of the most important process steps that has significant influence on the properties and the quality of lithium-ion cells.

Materials

CATHODE & ANODE ACTIVE MATERIAL (pCAM & CAM & AAM)

- Highly specialized and highly developed materials for Lithium-ion batteries

- Applied materials vary by application and requirement:

- Cathode (CAM, pCAM): NCM, Hi-Ni NCM, NCA, LCO, cathode precursors, ….

- Anode Active (AAM, pAAM): Graphite structured, Graphite-Si compounds anode precursors,…

- Each of these materials requires different special conditions in the thermal treatment process to achieve the desired properties.

- Thermal treatment control is one of the most important process steps that has significant influence on the properties and the quality of lithium-ion cells.