Rotary kiln

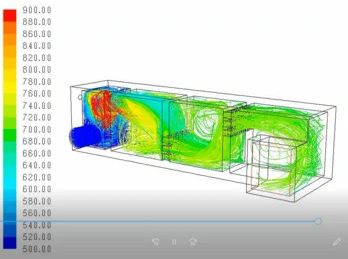

The rotary kiln (RK) with its initially basic design has been transformed into a thermal processing plant for the treatment of CAM and AAM, nearly all possible powders, specifically battery materials, under many different temperature and atmosphere conditions.

Gas tightness, high O2 applications, the implementation of complex mixing and dosing procedures as well as dealing with sticking and condensation problems have become standard features of these plants.

- No need for saggers or handling

- High output capacity due to excellent heat transfer and short cycle time

- Customized solution, tailored to your product

- Adjustable tilt and rotation speed

- Precise atmosphere adjustment inside the rotary tube

- Gas-tight feed system

- Cooling tube

Wide range of powder calcination and sintering processes

- High O2 atmosphere > 99 %

- Inert gas atmosphere (N2 , Ar, CO2 and others)

- Special atmosphere (N2 , CO, H2 , CH4 and others)

- Air atmosphere

Process equipment

TPC (Thermal Oxidizer) and extended process gas cleaning systems (bag house, cyclone, dry or wet scrubber) are available.

Thermal oxidizer (TPC) "thermal post combustion"

The purpose of a TPC is to burn off hydrocarbons contained in the process gas.

Extended process gas cleaning systems (bag house, cyclone, dry or wet scrubber)

The purpose of the extended process gas cleaning systems is the compliance with national and international emission limits.

We look forward to your inquiry!

Please complete the contact form below (*= mandatory fields). We will contact you immediately.

Your contacts

Christian Schwarz

Sales Manager

Riedhammer GmbH

90411 Nürnberg

Tel.: +49 911 / 52 18 411

E-mail: christian.schwarz@riedhammer.de

Andreas Hajduk

Sales Manager

Riedhammer GmbH

90411 Nürnberg

Tel.: +49 911 / 52 18 337

E-mail andreas.hajduk@riedhammer.de