The Riedhammer

services

Riedhammer offers a wide range of customer services with advanced, technological solutions for all firing processes.

Test and Application Center for:

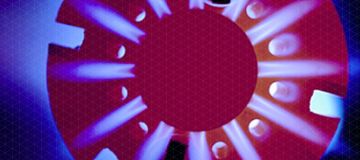

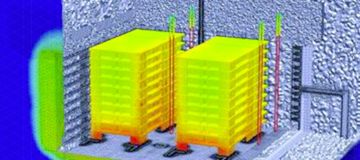

- Simulation of temperature distribution inside the product setting and/or kiln room, material analysis, improvement of kiln plant and processes, scientific base for product improvements.

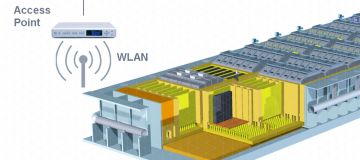

- Process Control System: individually designed for the specific applications.

- Revamping & Modernization: Sustainability though modernization of existing and active kilns in view of energy saving, waste gas aftertreatment, plant safety etc. as cost-efficient alternative to a new plant.

- Spare Parts: Comprehensive spare parts service for new and existing kiln plants with exclusively top-quality original spare parts and professional handling by experienced staff.

- Energy Efficiency: Integrated solutions for energy saving are our response to the increasing demands on the kiln plants in view of environmental protection.

Services

- Analysis of individual requirements

- Customized kiln solutions

- Design concepts

- Detailed offers

- Process engineering

- Production and testing

- Shipping, assembly, commissioning on site

- Documentation

- Production support

- Process analysis

- Maintenance

- Plant revamping

- Support for related processes and equipment via a broad network throughout the LiB industry

High manufacturing quality

- Well-equipped workshops

- Highlevel quality control management by Riedhammer / Sacmi

- Use of high-grade materials and components

- Quality and performance validation in our workshop (FAT)

- ISO 9001 certified

- Production tolerances compliant with German manufacturing standards

- Continuous development / improvement of equipment

- Special / tailor-made solutions

- Reliable suppliers

High efficiency

- Reliable long lifetime equipment

- Very low specific energy and media consumption

- High productivity

- Excellent temperature uniformity

- Strong, reliable sagger circulation and handling system

- Fully automated operation by PLC system

- Multiple temperature profiles available