Test & Application Center

Do you have specific requirements on your product?

We have the suitable technology! Use the experience of our Application Center to make your product more competitive!

Our Riedhammer Application Center (RAC) offers the following tests/analyses to find the optimal solution for each customer’s specific requirements:

- Development of optimal firing and atmosphere profiles

- Thermal analysis (Dilatometry, DTA (DSC), TG – DTG)

- Assessment of physical and thermal properties

- Firing tests in various kiln types and atmospheres (oxidising, reducing or inert gas)

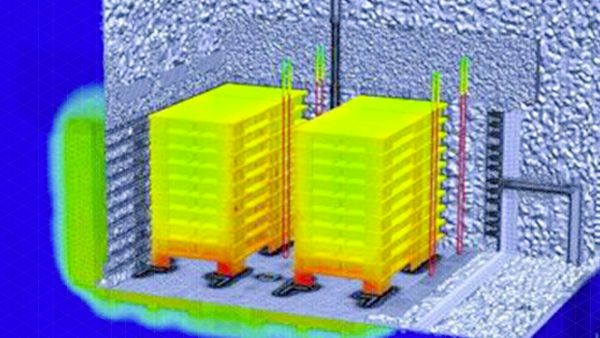

- CFD simulations of gas flow and heat transfer processes

- Validation tests of new components and kiln solutions

- Simulation of temperature distribution inside the product setting and/or kiln room.

Our kiln plant design process involves the development of firing technology, evaluation of highly exposed kiln components, testing of refractory materials, burners, heating elements and other kiln components, analysis of firing defects, emissions measurement and much more.

Riedhammer actively cooperates with renowned universities and research institutes and takes part in technical symposia, ensuring we are able to provide state-of-the-art innovation.

Material Analysis:

- Thermal Analysis

- Elaborating of the ideal firing curve

- Firing tests in continuous kilns

- between 0,5 h and 20 h up to 1450 °C

- in oxidizing and reducing firing atmosphere

- Firing tests in intermittent kiln plants up to 1800 °C

- in oxidizing and reducing firing atmosphere, low O2

- inert atmosphere, 50 ppm O2, 1400 °C

- Decoration firing of glass and ceramics

- Bending of glass panels

- Development of foaming processes

- Debindering and sintering tests (Low O2)

- Calcination of powders and bulk materials up to 1450 °C

Improvement of kiln plants and processes:

- Burner development

- Check and development of firing technology

- Evaluation of highly stressed kiln components and proposals for improvement

- Waste gas measuring and evaluation

- Steady and transient heat transfer and flow calculations as well as simulations

- Check and optimizing of debindering processes

- Evaluation of suitable processes for pre-sintering, calcining and expanding of powders, granulates and pellets

Scientific Basis:

- Close cooperation with universities and research institutes, support of dissertations and internships for university

- Regular technical publications

- Attendance at technical symposia